Huisman has developed a system that enables crane operators to anticipate and react to changing wind speeds, gusts, and direction during the installation of wind turbine blades.

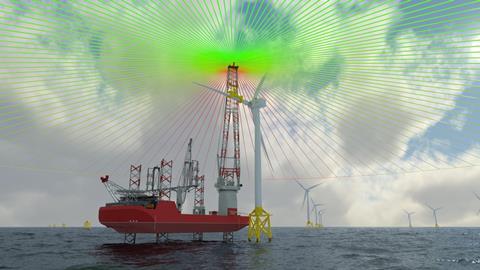

Called the Wind Gust Buster, the system assists crane operators and lifting supervisors when working with the installation of large objects at considerable height by providing information on the incoming wind, 360 degrees around the boom tip.

A LiDAR system, which measures the incoming wind on the crane’s boom tip, scans the horizontal area. This data is processed by the crane’s automation system and can be shown to both the crane operator as well as others involved. A typical prediction window, according to Huisman, is approximately five to eight minutes ahead of the incoming wind gust, which allows sufficient time to decide whether to proceed with the operation.

The system can be installed on newly built Huisman cranes as well as retrofitted to existing ones.

Cees van Veluw, product director cranes of Huisman, said: “We are constantly looking for new developments to further improve safety in turbine installation operations. Right now, sudden wind gusts acting on turbine blades can pose a safety risk to the people in the wind turbine, as well as an integrity risk to the blade and nacelle. While we all get used to checking the rain radar prior to taking a hike outside, we haven’t seen this used the same way in turbine installation before.

“The Wind Gust Buster improves the crane operator’s ability to mate the blade in a controlled manner and thus contributes to safety of the whole lifting operation. Furthermore, this can lead to less damage to components like the blade’s stud bolts, and thus can lead to a cost reduction and installation speed improvement.”